WDR type boiler product is a horizontal high-power steam boiler, the heater adopts ceramic electric heating tube, which has low surface load and long service life; Small flange connection, easy maintenance; its normal service life is about 20,000…

Email: [email protected]

Relying on a professional R&D team, Zhongtai Group strives to improve the actual operation effect of the boiler, pursues the service concept of taking science and technology as the guide and seeking survival by quality, and takes the lead in becoming the leading brand of electric heating boilers in China, with "domestic leading, international advanced".core competitiveness.

Zhongtai electric heating boilers are divided into LDR electric heating boilers, WDR electric heating boilers, CWDR electric heating boilers, etc. according to their structure, and can be divided into electric heating steam boilers and electric heating hot water boilers according to their functions. Electricity is one of the three types of clean energy vigorously promoted in my country. The Zhongtai Electric heating boiler uses electricity as energy and converts electric energy into heat energy. In the process of energy conversion, there is no need to provide the air and fuel required for combustion, so it will not emit Exhaust gas, waste residue, waste, etc., fully comply with the national environmental protection policy requirements.

Zhongtai electric heating boiler has a thermal efficiency of more than 98%, low noise during operation, stable and safe, and simple operation, and has been well received by customers!

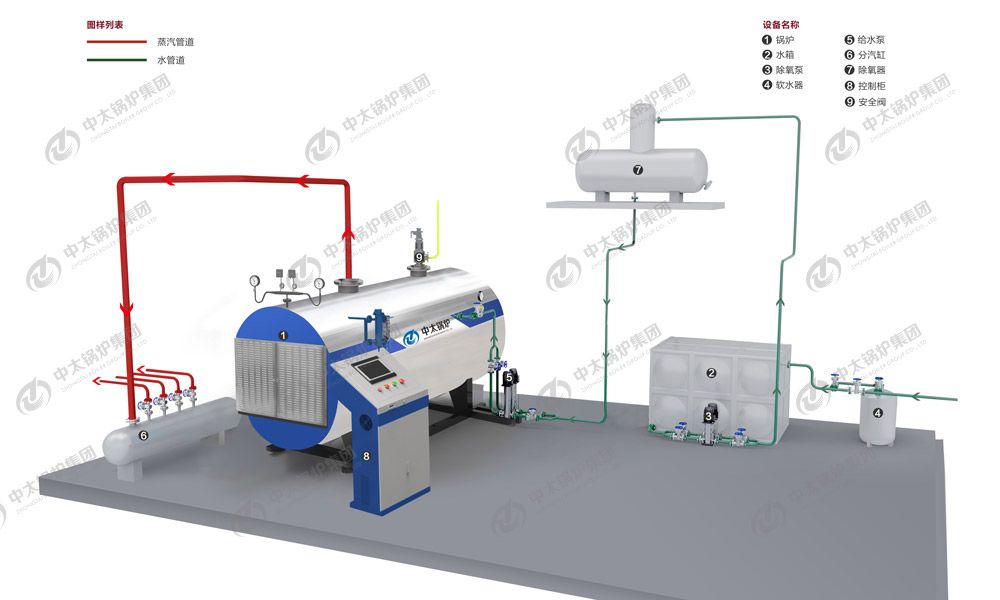

WDR type boiler product is a horizontal high-power steam boiler, which adopts the separation method of the electric control cabinet of the furnace body, which avoids the aging of electrical components and affects the service life; the heater adopts ceramic electric heating tube, which has low surface load and long service life; Small flange connection, easy maintenance; its normal service life is about 20,000 hours, the thermal efficiency is nearly 99%, the operation is quiet and clean, meets the requirements of environmental protection, and does not emit NOx (nitrogen oxides) into the atmosphere; PLC control system is used for the operation part, Free operation button, free indicator light, touch screen panel, Chinese and English display, man-machine dialogue, operation authorization, real-time information, automatic page turning.

Industrial field: steam required for the processing of industrial products such as textiles, printing and dyeing, paper making, food, rubber, plastics, chemicals, medicine, steel, metallurgy, etc.

Life field: heating, bathing, air conditioning and domestic hot water in enterprises, institutions, hotels, schools, catering, service and other industries.

1. Using advanced electric heating tube, each group of electric heating elements is connected by a centralized beam flange, set independently, with simple structure, high mechanical strength, safety and reliability, easy replacement, low surface load and long service life.

2. The boiler starts and stops quickly, the operating load adjustment range is large, the adjustment speed is fast, and the operation is simple.

3. The heating element automatically adjusts the number of input groups of heating tubes according to the temperature difference and load changes, and can automatically switch the input order, which not only saves energy consumption, but also balances the running time of each group of heating tubes, so as to uniformize the life of the heating tubes.

4. The heating element can also be manually put in or stopped, which is convenient for users to flexibly adjust the calorific value of the boiler.

5. Adopt advanced computer boiler controller PLC microcomputer programmable control and display screen, set its working pressure, working time and other functions through the man-machine interface, can display the equipment status, operating parameters and fault alarm; it has reliable performance and high degree of automation , easy to use and so on.

6. The electrical components have CE and CCC demonstration marks, select high-quality products at home and abroad, and have been tested for aging in the test furnace to ensure the long-term normal operation of the boiler.

7. The high-power electric steam boiler adopts the separation method of the furnace body and the control cabinet, which can be used in parallel with single or multiple sets, which avoids the influence of the use of electrical components due to heating.

Capacity: 0.35-14MW

Adapted Fuel: Electricity

Scope of application: Large hotels, schools, baths, government agencies, residential areas, chemical industry, smelting, building materials, etc.

| Model | Rated steam capacity (T/h) | Rated working pressure (Mpa) | Saturated steam temperature (℃) | Thermal efficiency (%) | Rated power (KW) | Design fuel | Max transport weight (KG) |

| WDR0.3-0.7 | 0.3 | 0.7 1.0 1.25 1.6 2.5 | 171 184 194 205 225 | ≥98 | 216 | Electricity | 950 |

| WDR0.5-0.7 | 0.5 | 360 | 1500 | ||||

| WDR0.7-0.7 | 0.7 | 504 | 1700 | ||||

| WDR1.0-0.7 | 1 | 720 | 1850 | ||||

| WDR1.0-1.0 | 1 | 720 | 1850 | ||||

| WDR2.0-0.7 | 2 | 1440 | 3000 | ||||

| WDR2.0-1.0 | 2 | 1440 | 3000 | ||||

| WDR2.0-1.25 | 2 | 1440 | 3100 | ||||

| WDR2.0-1.6 | 2 | 1500 | 3250 | ||||

| WDR2.0-2.5 | 2 | 1500 | 3360 | ||||

| WDR4.0-1.25 | 4 | 2880 | 6800 | ||||

| WDR6.0-1.6 | 6 | 4320 | 11000 |

Zhongtai Boiler is the professional manufacturer of Grade A industrial boilers, engages in industrial boiler design, manufacturing, transportation, installation, and after-sale service.

Contact Us