SZL boiler is a double-drum vertical chain furnace. The double-drum design of the furnace body makes this type of boiler have the advantages of large water capacity, large steam space and good steam quality. The convection heating surface of the…

Email: [email protected]

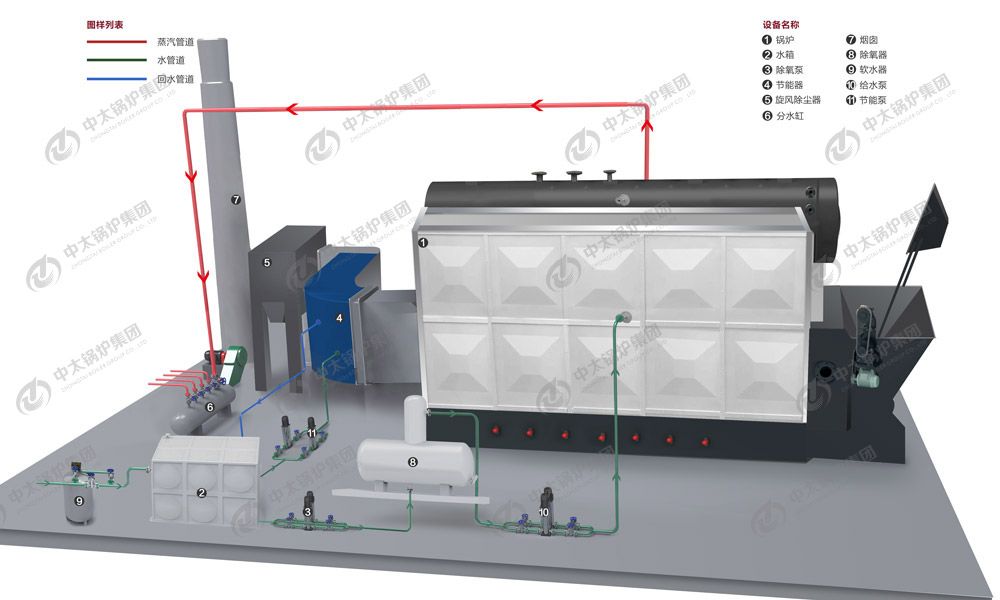

SZL boiler is a double-drum vertical chain furnace. The double-drum design of the furnace body makes this type of boiler have the advantages of large water capacity, large steam space and good steam quality. The convection heating surface of the boiler is large, which is stable during operation and has a certain overload operation capacity.

The boiler system has a high level of automation and perfect protection measures, such as automatic water supply adjustment, high and low water level alarm, overpressure protection, automatic flameout protection, etc., using professional design to ensure the smooth and safe operation of the boiler, and provide customers with convenient, efficient and safe services .

Food processing, rubber and plastic processing, greenhouse heating, smelting, hotels, catering and other industries

1.Membrane water-cooled wall structure is adopted on both sides of the furnace and the combustion chamber. The membrane-type water-cooling wall structure is an independent and original design of our company. The membrane-type water-cooling wall structure used for power station boilers is applied to the assembled boiler. The advantages are that the heat transfer coefficient is large, the heat transfer effect is good, the heat loss is low, and the air tightness is good. The furnace wall is not deformed or leaked.

2.The front and rear water wall pipes of the furnace extend down to the upper part of the grate to form the money and the rear arch. The structure is increased on the basis of the original mature bulk boiler, and on the basis of other heating areas remaining unchanged, the furnace radiant heating surface is added, and the overload capacity is stronger; Therefore, the defects of cracking and arch collapse of the original boiler three-fold line arch bricks during long-term high-temperature grilling are avoided, thereby prolonging the service life of the arch.

3.The furnace arch adopts the inverted "α" arch technology of "Second Prize of National Science and Technology Progress of Xi'an Jiaotong University". The front arch is high and short, and the rear arch is low and long, which increases the burning time of flue gas in the furnace and improves the Combustion efficiency; the streamlined rear arch throws unburned carbon particles blown up from the middle and rear of the grate to the front. Make the coal easier to ignite, and the ignition line is neat; the fuel adaptability is wide.

【Rated evaporation】: 4--30 t/h

【Rated steam pressure】: 0.7--2.5 Mpa

【Rated steam temperature】: 171--400 ℃

【Water temperature】: 20/105 ℃

[Applicable fuel]: biomass briquette fuel or bituminous coal

SZL series steam boiler

| Model | Rated steam capacity (T/h) | Rated working pressure (Mpa) | Saturated steam temperature (℃) | Heat efficiency (%) | Design fuel | Max transport weight (KG) | Max dimension (MM) |

| SZL4-1.25-T | 4 | 1.25/2.5 | 194/225 | 83 | Coal/ Biomass | 23000 | 6300x2300x3200 |

| SZL6-1.25-T | 6 | 25000 | 7700x2800x3450 | ||||

| SZL8-1.25-T | 8 | 27000 | 7800x3100x3520 | ||||

| SZL10-1.25-T | 10 | 30000 | 7900x3300x3640 | ||||

| SZL15-1.25-T | 15 | 40000 | 10000x3200x3500 | ||||

| SZL20-1.25-T | 20 | 45000 | 11000x3300x3500 |

SZL series pressure bearing hot water boiler

| Model | Rated heat power (MW) | Rated working pressure(Mpa) | Rated outlet/ Return temperature (℃) | Heat efficiency(%) | Design fuel | Max transport weight(KG) | Max dimension(M) |

| SZL4.2-1.0/115/70-T | 4.2 | 1 | 130/70 | 83 | Coal/ Biomass | 23000 | 10.2x3.2x5.8 |

| SZL5.6-1.0/115/70-T | 5.6 | 34000 | 11.7x3.5x5.9 | ||||

| SZL7.0-1.0/115/70-T | 7 | 35000 | 11.9x3.2x6.4 | ||||

| SZL10.5-1.0/115/70-T | 10.5 | 39000 | 12.6x4.6x6.7 | ||||

| SZL14-1.0/115/70-T | 14 | 45000 | 13.8x5.2x8.4 |

Zhongtai Boiler is the professional manufacturer of Grade A industrial boilers, engages in industrial boiler design, manufacturing, transportation, installation, and after-sale service.

Contact Us