DZL series quick-installed chain grate biomass boilers are single-drum vertical chain grate boilers. It is suitable for burning briquette biomass fuel, but also pure coal or mixed coal and briquette biomass fuel. There is an economizer at the rear.…

Email: [email protected]

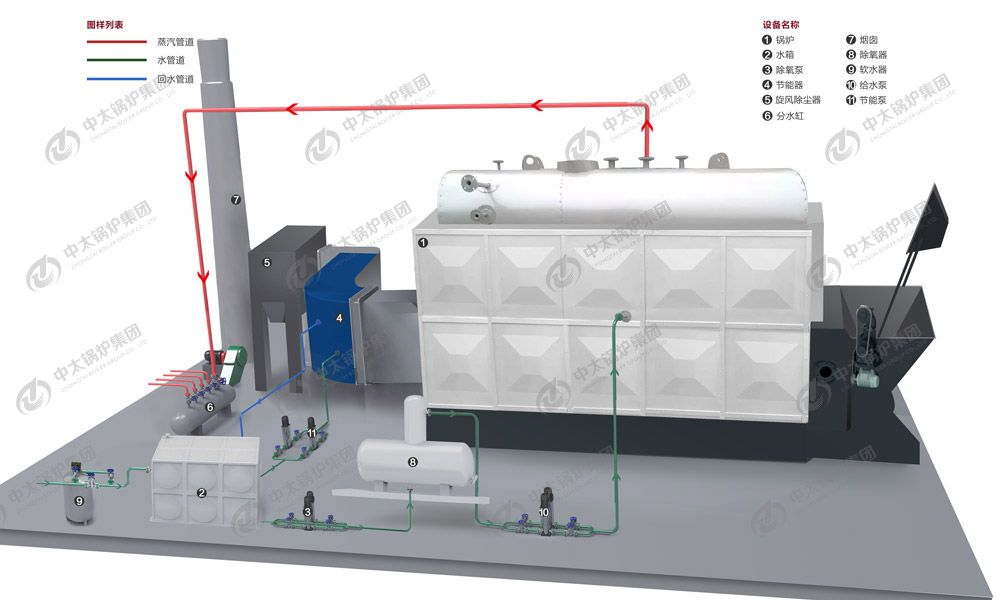

DZL series quick-installed chain grate biomass boilers are single-drum vertical chain grate boilers. It is suitable for burning briquette biomass fuel, but also pure coal or mixed coal and briquette biomass fuel. There is an economizer at the rear. The excluded ash and slag can be directly used as farmyard manure, which is a high-efficiency, energy-saving and environmentally friendly product. Equipped with a blower and induced draft fan for mechanical ventilation, and equipped with a screw slag extractor to achieve mechanical slag extraction, complete control and monitoring instruments, and safe and reliable boiler operation.

Combustion of briquette biomass fuel can also be used to provide thermal energy or generate electricity by burning coal alone or in combination with coal and briquette biomass fuel.

1. By pulling part of the rising pipes on the headers on both sides to the protective chamber, and then introducing them to the bottom of the drum side, supplemented by the bottom of the drum, the heating surface of the furnace top is formed by heat insulation. The novel furnace structure successfully solves the problem. The bottom of the cylinder is directly radiated by the high temperature flame to avoid the "bulge" defect.

2. The setting of the two-wing flue allows the flue gas to enter the front smoke box smoothly, so that the temperature of the previous tube sheet is the same, and the crack of the tube sheet due to temperature stress is avoided.

3.The single-return threaded smoke pipe is used in the drum to strengthen the heat transfer effect. At the same time, the threaded smoke pipe has the function of self-cleaning, which avoids the accumulation of dust in the smoke pipe.

4.Both the front and rear arches adopt an integral pouring structure supported by water-cooled wall tubes to form permanent arches. The arch design adopts the latest scientific research achievements of "Second Prize of National Science and Technology Progress of Xi'an Jiaotong University". The back arch is low and long, and the exit section is inversely inclined. It is conducive to the combustion of inferior coal, and the coal has strong adaptability.

5.The design of the grate side sealing structure is advanced and reasonable, which avoids the defect that the side seal is stuck on the grate and the air distribution on both sides of the grate is uneven and the side seal is burned out. Boilers of 4t/h and below use side-sealing cold-added angle iron rib plate structure, and boilers above 6t/h use contact-type side-sealing and lower-sealing structure.

6.There is an independent adjusting air chamber under the grate, and the air is fed on both sides; the new crank-arm screw adjustment structure is adopted, so that the cross-sectional ratio of air adjustment and ventilation can reach 100%; the adjustment is flexible and the air distribution is uniform. A push-pull gate ash cleaning device is designed, and the gate adopts a heat-resistant cast iron finish machining and sealing structure to effectively prevent secondary combustion deformation and grate air leakage.

【Rated evaporation】: 0.5--10 t/h

【Rated steam pressure】: 0.7--2.5 Mpa

【Rated steam temperature】: 171--225 ℃

【Water temperature】: 20/105℃

【Applicable fuel】: Formed biomass fuel; bituminous coal; mixed fuel of bituminous coal and biomass

DZL series steam boiler

| Model | Rated steam capacity (T/h) | Rated working pressure (Mpa) | Saturated steam temperature (℃) | Heat efficiency (%) | Design fuel | Max transport weight(KG) | Max dimension(MM) |

| DZL0.5-1.25-T | 0.5 | 1.25 | 194 | 83 | Coal/ Biomass | 11000 | 3300x2000x2656 |

| DZL1-1.25-T | 1 | 15000 | 5200x2100x2600 | ||||

| DZL2-1.25-T | 2 | 23000 | 5650x2400x2700 | ||||

| DZL3-1.25-T | 3 | 24000 | 5700x2600x2800 | ||||

| DZL4-1.25-T | 4 | 29000 | 6850x2700x3200 | ||||

| DZL6-1.25-T | 6 | 32000 | 6800x2900x3400 | ||||

| DZL8-1.25-T | 8 | 35000 | 7200x3200x3800 | ||||

| DZL10-1.25-T | 10 | 40000 | 7900x3400x5500 |

DZL series pressure bearing hot water boiler

| Model | Rated heat power (MW) | rated working pressure (Mpa) | Rated outlet/Return temperature (℃) | Heat Efficiency (%) | Design fuel | Max transport weight (KG) | Max dimension (MM) |

| DZL0.35-1.0/115/70-T | 0.35 | 1 | 130/70 | 83 | Coal/ Biomass | 11000 | 3300x2000x2656 |

| DZL0.7-1.0/115/70-T | 0.7 | 14500 | 4800x2150x2960 | ||||

| DZL1.4-1.0/115/70-T | 1.4 | 25000 | 5280x2380x3030 | ||||

| DZL2.1-1.0/115/70-T | 2.1 | 26000 | 5500x2420x3250 | ||||

| DZL2.8-1.0/115/70-T | 2.8 | 28000 | 6000x2500x3400 | ||||

| DZL4.2-1.0/115/70-T | 4.2 | 30000 | 7200x2600x3800 | ||||

| DZL5.6-1.0/115/70-T | 5.6 | 35000 | 7600x2800x4200 | ||||

| DZL7.0-1.0/115/70-T | 7 | 40000 | 8000x3200x5580 |

Zhongtai Boiler is the professional manufacturer of Grade A industrial boilers, engages in industrial boiler design, manufacturing, transportation, installation, and after-sale service.

Contact Us